Top Bamboo Charcoal Wood Veneer Panel Manufacturers in China: Quality and Innovation

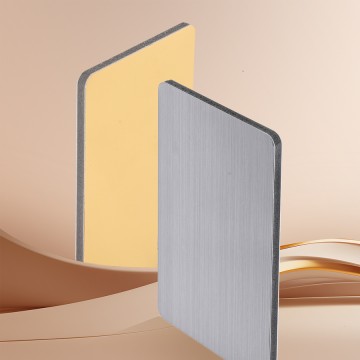

Crafted with precision and an emphasis on sustainability, our Bamboo Charcoal Wood Veneer Panels merge aesthetic elegance with eco-conscious design. These panels highlight the natural beauty of bamboo while leveraging the innovative properties of charcoal, known for its capacity to absorb odors and regulate moisture, thereby enhancing indoor air quality. Suitable for a variety of applications including interior design, furniture making, and architectural projects, our veneer panels are versatile and easy to work with. The sustainable nature of bamboo reduces environmental impact, aligning with contemporary sustainability goals. With advanced manufacturing processes, Shandong Xiangying New Materials Technology Co., Ltd. ensures the highest quality and craftsmanship. Elevate your designs with our Bamboo Charcoal Wood Veneer Panels, where nature harmonizes with innovation to bring beauty and functionality together.Expert Tips For Bamboo Charcoal Wood Veneer Panel Manufacturers Factory-Direct Excellence Industry Giant

When it comes to sourcing bamboo charcoal wood veneer panels, manufacturers play a crucial role in delivering quality and excellence directly from the factory. With over a decade of experience in the industry, our company is dedicated to maintaining the highest standards of service and product integrity. We believe in the power of trust and support, fostering mutually beneficial relationships with our clients. Our commitment to win-win cooperation has positioned us as a leading giant in the bamboo charcoal veneer market. To ensure that you make the best choice for your projects, consider the following expert tips: Firstly, prioritize manufacturers who demonstrate transparency in their production processes. This ensures not only quality products but also sustains ethical practices. Secondly, look for companies that invest in innovation and technology to enhance their product offerings. Our factory continuously researches and develops new techniques to improve the quality and durability of our veneer panels. Lastly, always assess the level of customer service and post-purchase support offered by the manufacturer. With us, you will find a dedicated team ready to assist you at every stage of your procurement process. Choosing the right factory-direct supplier can significantly impact your business. By partnering with a reputable company like ours, you can rest assured that you are receiving top-notch bamboo charcoal wood veneer panels, supported by years of expertise and commitment to excellence. Let us help you achieve your goals while ensuring quality and sustainability in every product you source.

Expert Tips For Bamboo Charcoal Wood Veneer Panel Manufacturers Factory-Direct Excellence Industry Giant

| Tip Category | Description | Importance Level | Implementation Stage |

|---|---|---|---|

| Material Sourcing | Ensure high-quality bamboo charcoal is sourced from sustainable farms. | High | Pre-production |

| Manufacturing Process | Implement advanced manufacturing technology to improve efficiency. | Medium | Production |

| Quality Control | Establish strict quality control measures to ensure product standards. | High | Post-production |

| Market Research | Conduct regular market research to stay ahead of industry trends. | Medium | Ongoing |

| Customer Feedback | Gather and analyze customer feedback for continuous improvement. | High | Post-sales |

Best Ways To Bamboo Charcoal Wood Veneer Panel Manufacturers Factory For the Current Year

C

Charles Martinez

A fantastic product! The high level of customer service continued long after my purchase, showing their commitment to quality.

02 June 2025

T

Thomas Clark

This product has surpassed my expectations. The after-sales support was reliable and very well-informed.

07 July 2025

S

Sophia King

A fantastic buy! The quality is top-tier, and the professionalism of the support team is something to commend.

04 July 2025

E

Evelyn Clark

Amazing quality! The support staff were not only professional but also very understanding.

12 July 2025

M

Madison Scott

Fantastic experience! The quality of the item is high, and the support service was exemplary.

16 June 2025

J

James Kowalski

Outstanding quality! The support team was very adept in handling my inquiries and demonstrated great professionalism.

11 June 2025

Hot Selling

Hot Selling