Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

In recent years, the construction and design industries have increasingly embraced innovative materials that combine durability with aesthetic appeal. One such material that has gained significant popularity is Paneles WPC (Wood Plastic Composite Panels). These panels are crafted from a mixture of wood fibers and plastic, resulting in a versatile product that is not only resistant to moisture and pests but also available in a variety of finishes and colors. As we look ahead to 2025, the demand for sustainable and effective building materials continues to grow, making WPC panels a top choice for architects, builders, and homeowners alike.

The advantages of Paneles WPC extend beyond their durability; they also offer an environmentally friendly alternative to traditional wood products. With an array of design options, these panels can seamlessly integrate into various architectural styles, from modern to rustic. This flexibility, combined with their low maintenance requirements, positions WPC panels as a leading contender for anyone seeking to enhance their living or working spaces. In our comprehensive overview of the best options available in 2025, we will explore the most reliable WPC panels that balance performance with visual appeal. Ultimately, this guide aims to equip readers with insights that encourage informed decisions in material selection for future projects.

Wood-Plastic Composite (WPC) panels have surged in popularity over the past few years, becoming a favored choice for both residential and commercial applications. These innovative materials combine the aesthetics of traditional wood with the durability of synthetic materials, making them exceptionally versatile and appealing to a wide range of consumers. WPC panels are primarily made from a blend of wood fibers and recycled plastics, offering an environmentally friendly alternative to solid wood, while also resisting moisture, rot, and insects.

The growing interest in WPC panels can be attributed to several factors including their long-term performance and design flexibility. Homeowners and builders appreciate their resistance to weather elements, which ensures longevity and reduces maintenance needs. Additionally, WPC panels come in a variety of finishes and colors, allowing designers to achieve the desired aesthetic while benefiting from the inherent strength of the composite material. This combination of durability and design makes WPC panels an increasingly popular choice for decking, siding, and even indoor applications, signaling a shift towards more sustainable building materials in the industry.

| Panel Type | Durability (Years) | Design Flexibility | Environmental Impact | Cost ($/sqft) |

|---|---|---|---|---|

| Classic WPC | 15-25 | High | Recyclable | 3.50 |

| Composite WPC | 20-30 | Moderate | Low | 4.00 |

| High-Performance WPC | 25-40 | Very High | Recyclable | 5.50 |

| Eco-Friendly WPC | 15-20 | Moderate | High | 4.25 |

When selecting WPC panels for construction or renovation projects, durability and design are two key characteristics that significantly influence their performance and aesthetic appeal. Durable WPC panels are designed to withstand harsh environmental conditions, such as moisture and UV exposure, which are common challenges in outdoor settings. The composite materials used in WPC construction enhance its strength, making it resistant to warping, splintering, and rotting. This longevity means that WPC panels require less maintenance over time compared to traditional materials, making them a smart choice for both residential and commercial applications.

In terms of design, WPC panels offer versatility with a range of textures, colors, and finishes that can complement various architectural styles. These panels can mimic the natural look of wood while providing the added benefits of composite materials, such as ease of cleaning and resistance to pests. Many designs also allow for customization, giving homeowners and designers the freedom to create unique looks that enhance the overall aesthetic of the space. As sustainability becomes increasingly important, WPC panels made from recycled materials not only provide a stylish finish but also contribute to environmentally friendly building practices, making them an attractive option for modern construction.

This chart illustrates the key characteristics of the top WPC panels for 2025, focusing on durability attributes such as water resistance, UV resistance, impact resistance, design versatility, and maintenance ease. The ratings are expressed as percentages reflecting the effectiveness in each category.

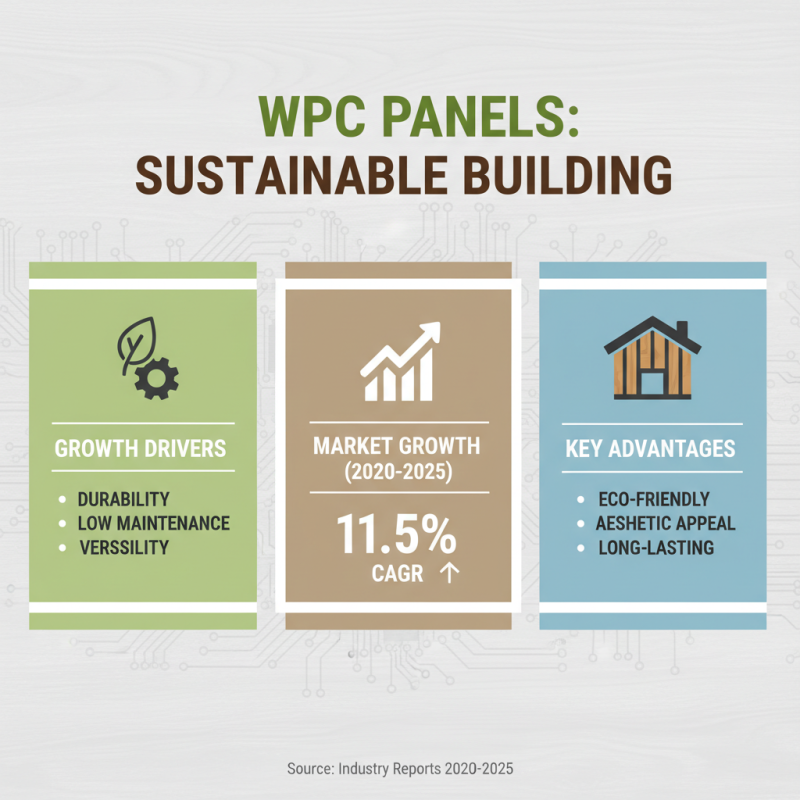

The market for Wood Plastic Composite (WPC) panels is poised for significant growth as we head into 2025. This trend is driven by the increasing demand for sustainable and durable building materials. According to a recent industry report, the WPC market is expected to reach USD 10.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 11.4% from 2020. This growth indicates that more manufacturers are investing in innovative designs and production processes to enhance the performance and aesthetic appeal of WPC panels.

Leading manufacturers are increasingly focusing on eco-friendly practices and advanced technology. Many are utilizing recycled materials in their production, contributing to the sustainability of WPC panels. An industry analysis highlights that nearly 60% of the top companies are incorporating environmentally responsible materials to meet consumer demands. Additionally, enhancements in color stability and texture are becoming focal points, allowing for greater customization in design.

Tips: When selecting WPC panels, consider their resistance to moisture and pests, which greatly influences long-term durability. Moreover, look for panels with better UV resistance, as this will ensure that colors remain vibrant over time. Lastly, always check for certifications from manufacturers that indicate compliance with environmental standards, ensuring that you’re making an eco-conscious choice.

As the demand for sustainable and aesthetically pleasing building materials increases, Wood Plastic Composite (WPC) panels have emerged as a leading option in the market. In recent years, the market for WPC panels has shown significant growth, with industry reports projecting a compound annual growth rate (CAGR) of approximately 11.5% from 2020 to 2025. This surge is largely attributed to their durability, low maintenance requirements, and versatility in design applications.

A comparative analysis of the various WPC panel options reveals that many products are now designed with advanced technology to enhance their resistance to moisture, UV rays, and pests. For instance, studies indicate that panels with higher wood fiber content generally offer better rigidity and strength, while those incorporating more thermoplastics tend to provide superior weather resistance. Furthermore, some recent evaluations highlight that consumers are gravitating toward panels that offer a balance of durability and aesthetic appeal, with the demand for natural wood-like finishes increasing by over 20% in the last two years.

Moreover, the eco-friendliness of WPC panels is a significant consideration for many buyers. Reports suggest that nearly 70% of consumers prioritize sustainable materials, driving manufacturers to focus on sourcing recycled wood fibers and plastics for their products. This alignment with environmental goals not only boosts marketability but also contributes to the overall value proposition that modern WPC panels deliver, showcasing their ability to meet both design and durability standards efficiently.

The production of Wood-Plastic Composite (WPC) panels has evolved significantly in recent years, with a growing emphasis on sustainability. According to a report by Research and Markets, the global WPC market is projected to reach $9.4 billion by 2025, driven by increased demand from the construction industry seeking eco-friendly materials. WPC panels are often made from recycled wood fibers and plastics, significantly reducing waste and offering a renewable alternative to traditional building materials. This aligns with the global shift towards a circular economy, where resource efficiency and waste reduction are paramount.

Moreover, the lifecycle assessment of WPC panels indicates that their production consumes less energy compared to conventional materials like PVC and solid wood. The American Composites Manufacturers Association reports that WPC technology can reduce greenhouse gas emissions by approximately 50% in comparison to typical wood products. In addition, many WPC manufacturers are investing in sustainable sourcing practices, ensuring that the raw materials used are responsibly harvested and that the production processes adhere to stringent environmental standards. This focus on sustainability not only meets consumer demand but also aligns with regulatory pressures for greener building solutions, making WPC panels a compelling option for future developments in the construction sector.