Shandong Xiangying New Materials Technology Co., Ltd.

Shandong Xiangying New Materials Technology Co., Ltd.

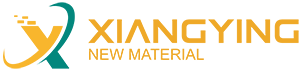

In recent years, the demand for WPC panels has surged, driven by their exceptional durability, aesthetic appeal, and environmentally friendly properties. According to a report by MarketsandMarkets, the global WPC market is projected to reach $6.8 billion by 2025, expanding at a CAGR of 12.4%. As more industries recognize the advantages of using wood-plastic composites—such as lower maintenance costs and resistance to moisture—leading Chinese manufacturers have emerged as frontrunners in this competitive landscape. These manufacturers not only meet stringent quality standards but also leverage advanced technology to ensure that their WPC panels offer unmatched performance for various applications, ranging from decking to wall cladding. This blog will guide you through the superior qualities of WPC panels, showcasing how they can elevate your projects while contributing to a sustainable future.

When choosing WPC (Wood Plastic Composite) panels, it’s essential to understand the key factors that influence their quality and performance. Firstly, consider the material composition. High-quality WPC panels boast a balanced mix of wood fibers and plastic, enhancing durability while reducing susceptibility to warping and fading. Always confirm the manufacturer’s specifications to ensure you’re selecting a product that meets your needs.

Tip: Check for eco-friendliness! Many leading Chinese manufacturers emphasize sustainable sourcing, so look for certifications that validate their commitment to the environment.

Another critical factor is the panel's thickness and density. Thicker panels typically offer better stability and resistance to damage. Additionally, a denser composition often translates to enhanced durability, making it imperative to assess these attributes before making a purchase.

Tip: Evaluate the warranty offered by the manufacturer. A robust warranty can be a good indicator of the panel's quality, ensuring you have coverage for potential defects or performance issues.

By focusing on these critical aspects, you can choose superior WPC panels that meet your project’s demands while benefiting from the unmatched quality provided by leading manufacturers.

WPC (Wood Plastic Composite) panels are rapidly becoming the material of choice for construction and design, thanks to their unique blend of durability and eco-friendliness. According to a recent market report by MarketsandMarkets, the WPC market is projected to reach USD 9.7 billion by 2025, highlighting a significant growth trajectory. This surge is primarily due to the myriad of benefits WPC panels offer over traditional materials such as wood and plastic.

One of the standout advantages of WPC panels is their resistance to moisture and insect damage, which makes them ideal for outdoor applications. Industry studies indicate that WPC can last up to 25 years without significant deterioration, while traditional wood typically requires more frequent maintenance and replacement. Furthermore, WPC’s composition allows for minimal waste during production, making it a sustainable choice—an aspect that resonates with the growing eco-conscious consumer base, as evidenced by a survey from Nielsen that showed 66% of global consumers are willing to pay more for sustainable brands. This combination of durability, reduced maintenance costs, and environmental benefits positions WPC panels as a superior alternative in today’s building materials market.

One of the standout advantages of WPC panels is their resistance to moisture and insect damage, which makes them ideal for outdoor applications. Industry studies indicate that WPC can last up to 25 years without significant deterioration, while traditional wood typically requires more frequent maintenance and replacement. Furthermore, WPC’s composition allows for minimal waste during production, making it a sustainable choice—an aspect that resonates with the growing eco-conscious consumer base, as evidenced by a survey from Nielsen that showed 66% of global consumers are willing to pay more for sustainable brands. This combination of durability, reduced maintenance costs, and environmental benefits positions WPC panels as a superior alternative in today’s building materials market.

When it comes to finding high-quality WPC (Wood Plastic Composite) panels, leading Chinese manufacturers stand out for their exceptional offerings. One of the top features of these panels is their remarkable durability. Unlike traditional wood, WPC panels resist warping, cracking, and splintering, making them ideal for various applications, including decking, wall cladding, and outdoor furniture. This enhanced longevity ensures that homeowners and builders can enjoy the aesthetics of wood without the frequent maintenance and replacement expenses.

Another significant advantage of WPC panels from Chinese manufacturers is their eco-friendliness. Produced from recycled wood and plastic materials, these panels contribute to sustainable building practices. The manufacturing processes are designed to minimize waste, and the finished product is free from harmful chemicals often found in conventional wood treatments. Additionally, the versatile design options available allow for endless customization, making WPC panels not only functional but also aesthetically pleasing, suitable for any style preference. As more industries recognize these benefits, Chinese WPC panels continue to gain popularity worldwide.

When considering the purchase of Wood-Plastic Composite (WPC) panels, evaluating their durability and maintenance requirements is crucial. According to a recent industry report by MarketsandMarkets, the global WPC market is projected to grow at a CAGR of 12.2%, highlighting the increasing consumer demand for sustainable and durable building materials. WPC panels are renowned for their resistance to moisture, decay, and pests, making them an excellent choice for both indoor and outdoor applications.

Moreover, maintenance of WPC panels is substantially lower compared to traditional wood. A study by the American Wood Council indicates that WPC panels require approximately 50% less maintenance over their lifespan than wood alternatives, due to their inherent properties that resist fading, staining, and warping. While initial costs may be higher, the long-term benefits of reduced maintenance and longer lifespan—often exceeding 25 years—make WPC panels a cost-effective and reliable choice for those seeking uncompromised quality and durability.

When sourcing WPC (Wood Plastic Composite) panels from leading Chinese manufacturers, it’s essential to prioritize quality verification. According to a report from MarketsandMarkets, the global WPC market is expected to reach $9.5 billion by 2025, driven by the construction and automotive sectors. As demand rises, ensuring that suppliers adhere to high manufacturing standards becomes crucial. Look for certifications such as ISO 9001 and EN 15534, which indicate a commitment to quality and sustainability.

Moreover, conducting factory audits can greatly enhance your sourcing strategy. In a recent survey by Statista, approximately 70% of companies reported difficulties in ensuring product quality when sourcing internationally. By implementing a rigorous verification process—including third-party inspections and sample testing—you can mitigate risks associated with inferior products. Furthermore, collaborating with suppliers who demonstrate transparency in their production processes often yields better long-term partnerships.