PRODUCT

INTRODUCTION

Wood plastic composite co-extrusion decking is a high-tech, green and environmentally friendly material mainly made of wood (wood cellulose, plant cellulose) as the base material, thermoplastic polymer materials (plastics) and processing aids, mixed evenly, and then heated and extruded by mold equipment. It combines the properties and characteristics of wood and plastic, and is a new type of environmentally friendly high-tech material that can replace wood and plastic.

PRODUCT INTRODUCTION

| Place of Origin: | China | Applications: | Platforms for landscaping, architecture, etc |

| Product Name: | Wood plastic composite decking | Advantages: | Environmental protection, weather resistance, fire resistance, waterproofing |

| Model: | XY-140-23 | Usage: | Outdoor |

| Material: | Wood plastic composite material | Style: | Hollow or Solid |

| Surface treatment: | co-extrusion | Service life: | Over 25 years |

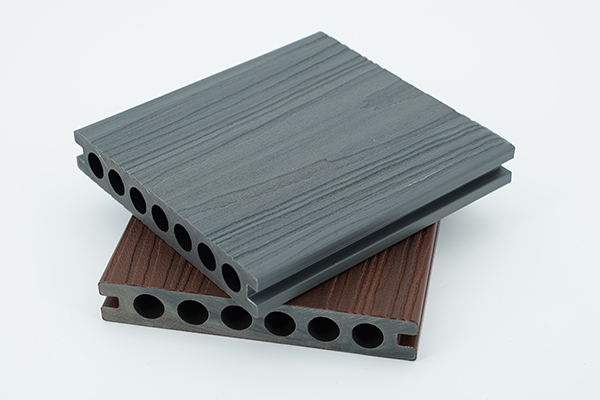

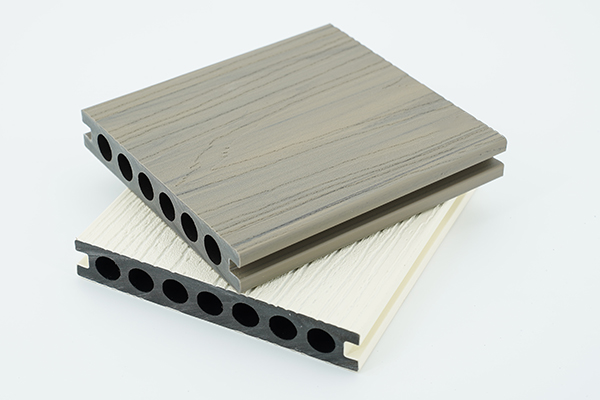

DIVERSE COLORS

There are many colors, with the natural appearance and texture of natural wood

You can customize the desired color according to your personality

No maintenance or upkeep required, easy to clean

UV resistant, color stable

Weather resistance (MPa) ≥ static flexural strength 16

HIGH PROCESSING PERFORMANCE

Having secondary processing properties of wood

Sawable, planing, bonding, fixing with nails or screws

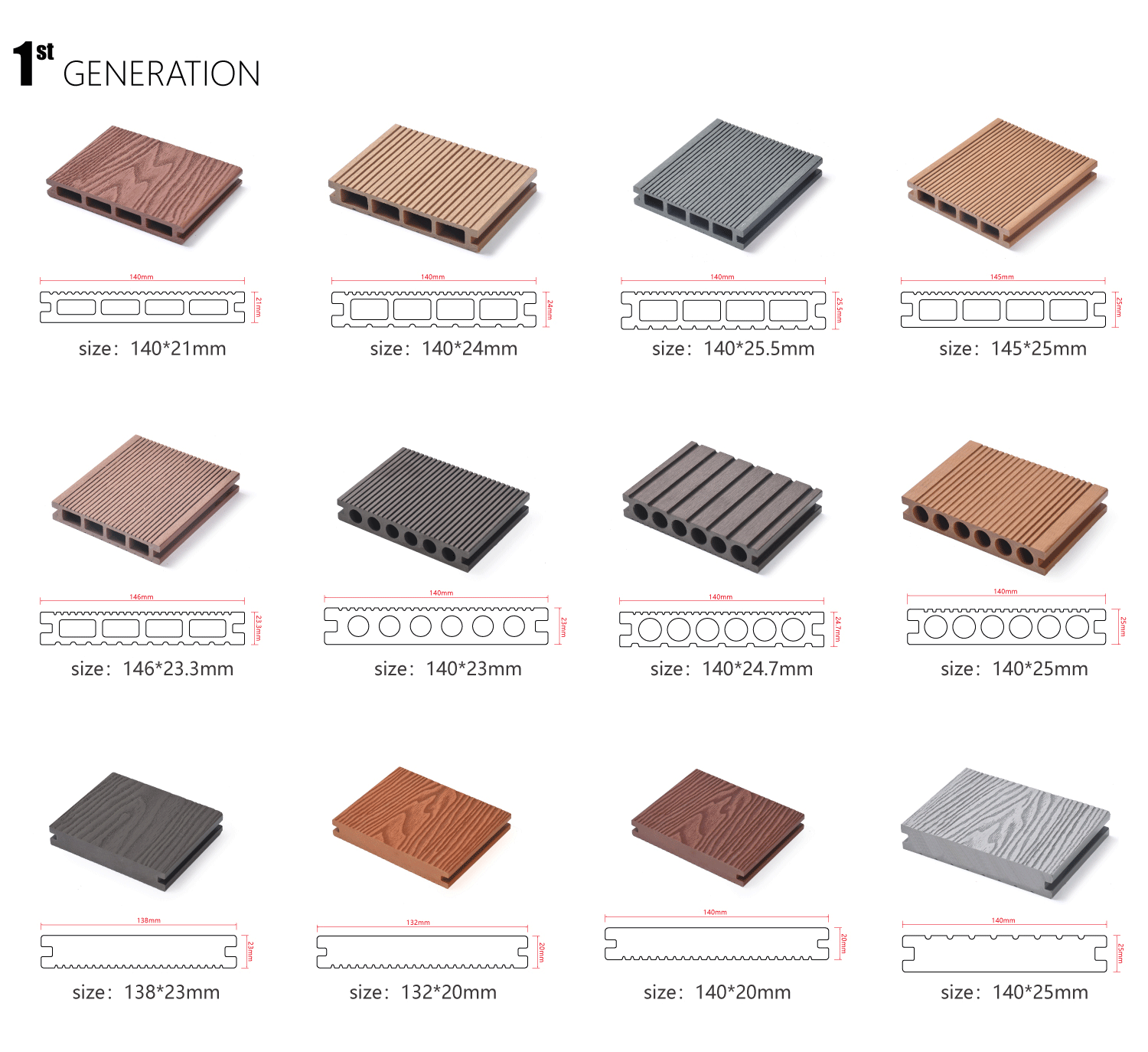

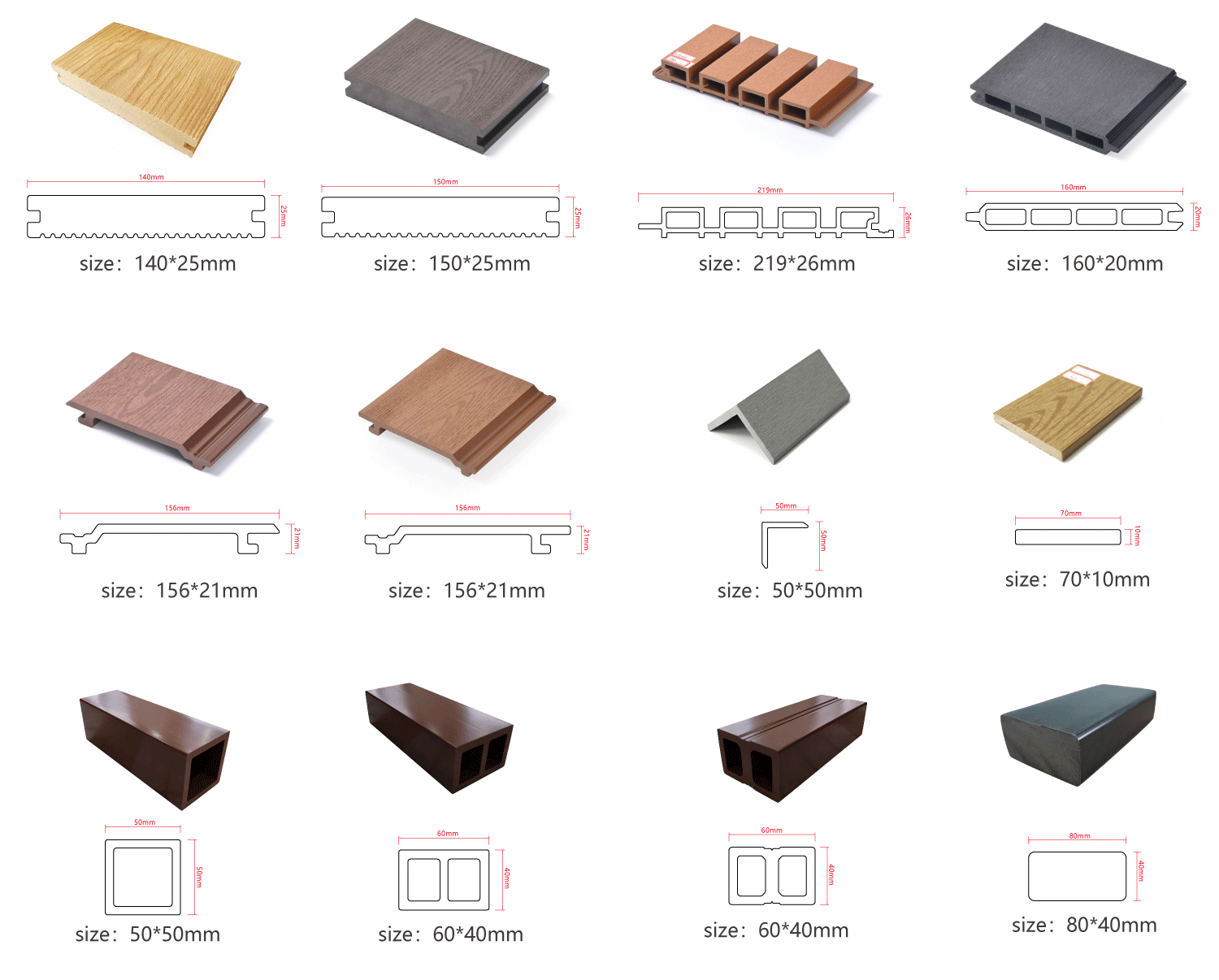

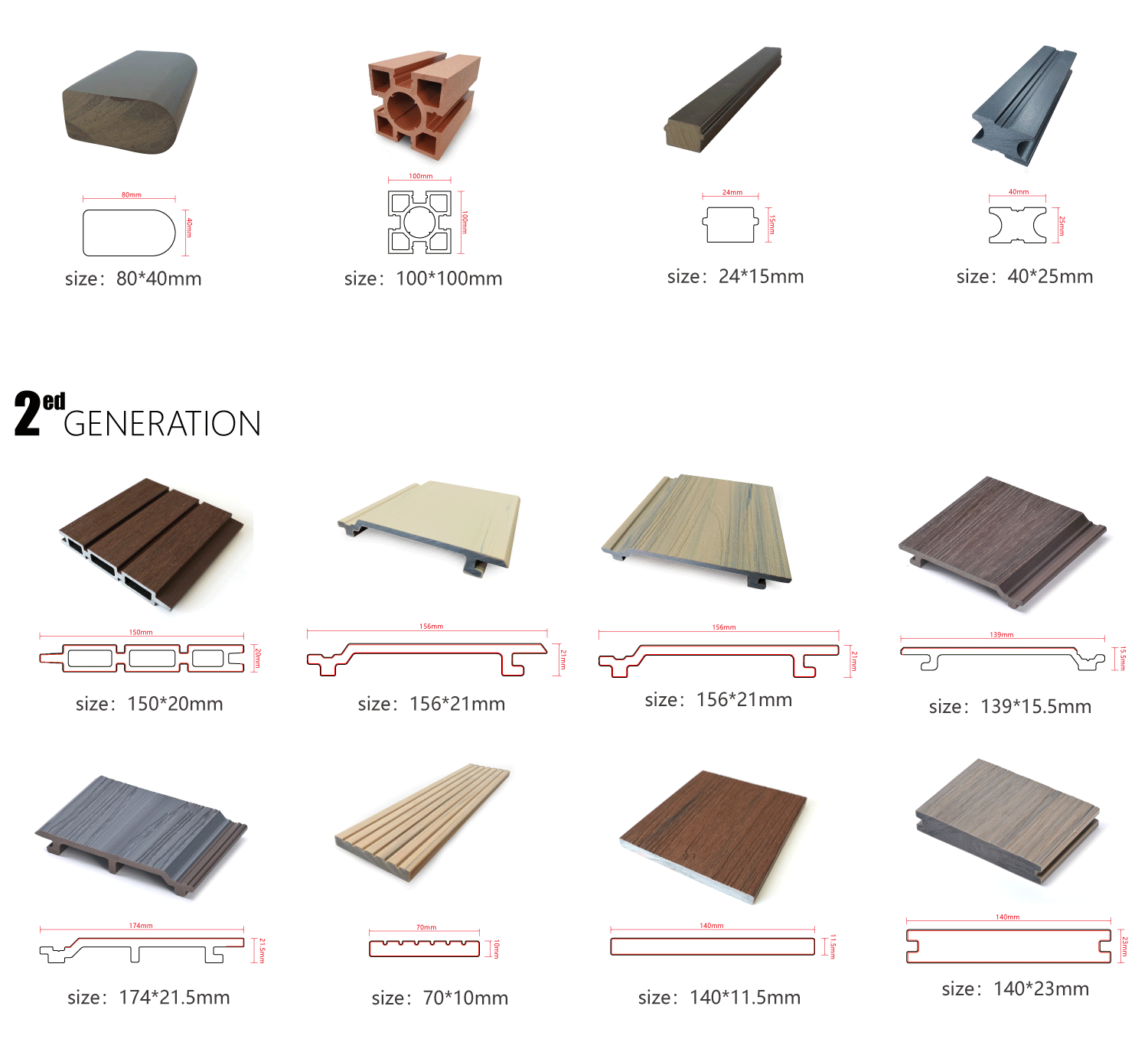

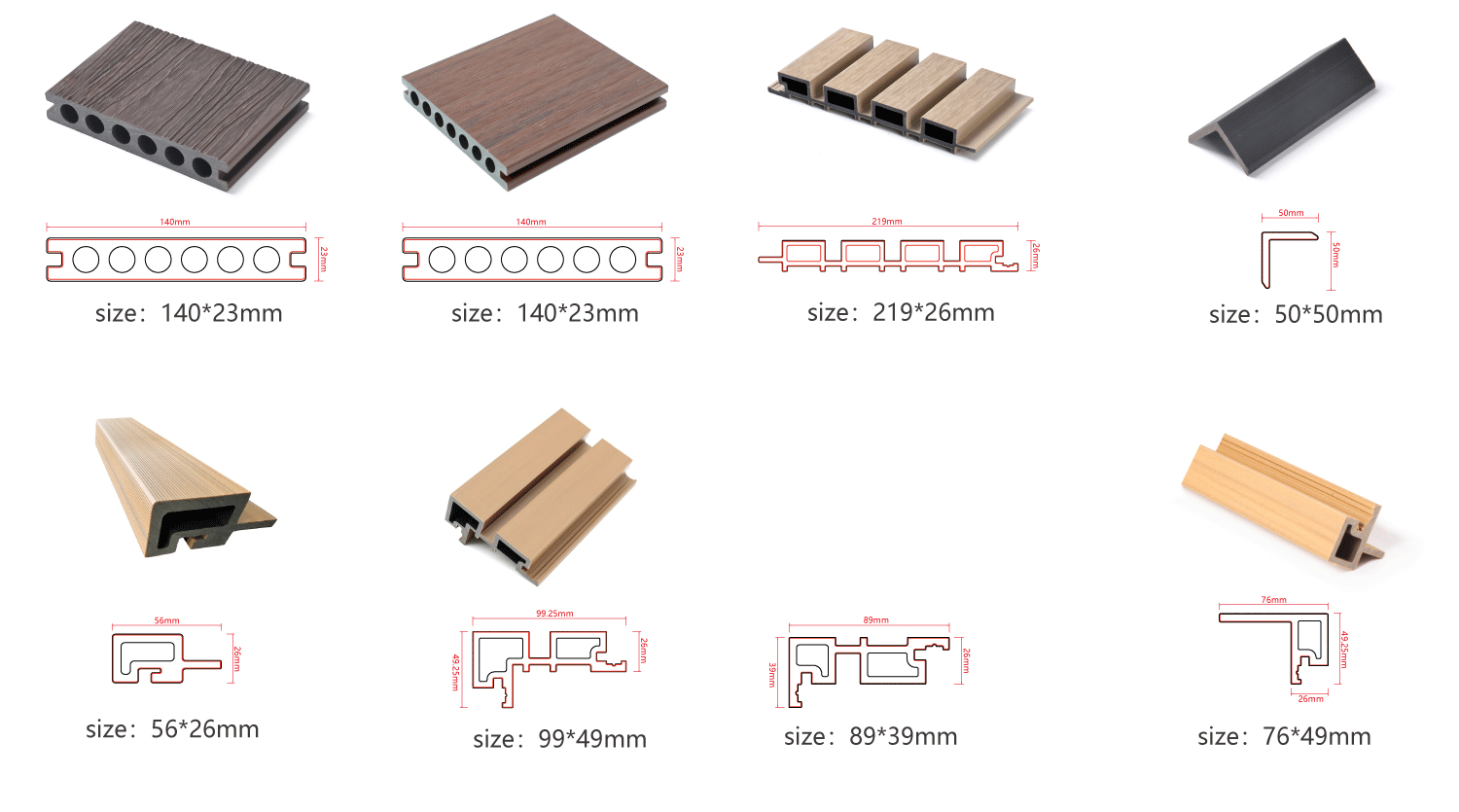

Various profile specifications and standards, quick and convenient installation

Gripping force (N) ≥ 1000

Bending modulus of elasticity (MPa) ≥ 1800

Surface wear resistance (G/100r) ≤ 0.08

THE TEXTURE OF WOOD

Better stability than wood, no wood knots or scars

Will not produce cracks, warping, or deformation

Multiple colors, no need for secondary painting, never fading

The surface does not require secondary painting

Waterproof and moisture-proof

-

Features and Advantages

+ -Sound absorption effect:

The back panel adopts Ixpe and cork soundproof pad, which has a certain sound absorption effect.

Insect and mildew prevention:

Plastic itself has the characteristics of waterproofing, mildew resistance, and corrosion resistance, making it less susceptible to insect infestation. The surface is also coated with antibacterial agents, effectively inhibiting bacterial growth.

Good processing performance:

WPC flooring has good processing performance, can be sawed, nailed, and planed, and has better nail holding force than other synthetic materials.

High intensity:

It has a good elastic modulus, significantly better durability than ordinary wooden materials, and high surface hardness.

Water and corrosion resistance:

WPC materials are resistant to strong acid and alkali, water, and corrosion, with a long service life of over 50 years.

-

Product Catalog

+ -

-

Application Scenarios

+ -WPC flooring is also suitable for large-scale commercial facilities and public projects, such as swimming pools, hotels, docks, etc.

Hot Selling

Hot Selling