Top PVC Wall Paneling Suppliers & Factories in China - Premium Quality Panels

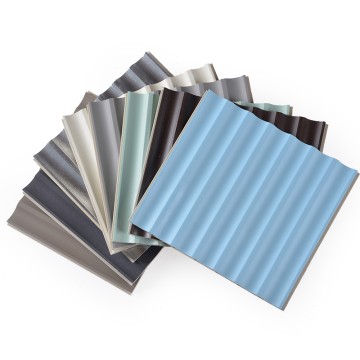

Transform your space with top-quality PVC wall panels from Shandong Xiangying New Materials Technology Co., Ltd. Our innovative panels combine a modern look with durability and easy maintenance. Made from premium PVC, these wall panels are water-resistant, lightweight, and easy to install, suitable for both residential and commercial use. Available in a range of colors, patterns, and finishes, they enhance any interior style, from contemporary to rustic. In addition to improving visual appeal, our panels offer excellent insulation properties. With a commitment to sustainability, our manufacturing process minimizes environmental impact. Whether renovating a home or outfitting a business, our PVC wall panels provide a versatile and cost-effective solution, ensuring quality materials that fulfill your design aspirations.Key Methods For Pvc Wall Paneling Sheet Factory Where Innovation Meets 2025 Supplier

In the dynamic landscape of interior design and construction, PVC wall paneling has emerged as a versatile solution, marrying function with innovative aesthetics. As we approach 2025, the demand for high-quality and sustainable materials grows, presenting remarkable opportunities for suppliers. Our factory embodies this evolution, focusing on cutting-edge methods that enhance both production efficiency and product quality. With over a decade of industry experience, we pride ourselves on our unwavering commitment to innovation, ensuring that our PVC wall panels meet the highest standards while catering to diverse client needs. At the heart of our operations is a dedication to service and sincerity. We believe in forging strong partnerships built on trust and mutual benefit. Our clients around the globe receive not just top-tier products but also personalized support throughout their purchasing journey. Whether for large-scale projects or bespoke installations, our team is equipped to facilitate seamless transactions that prioritize customer satisfaction. As we look forward to 2025, we invite global buyers to explore our commitment to excellence in PVC wall paneling, where innovative design meets reliable supply. Together, let's harness the potential of quality materials to create spaces that inspire and endure.

Key Methods For PVC Wall Paneling Sheet Factory Where Innovation Meets 2025 Supplier

| Method | Description | Innovation Aspect | Expected Impact by 2025 |

|---|---|---|---|

| Automated Production Line | Integration of robotics to enhance speed and precision in manufacturing. | Increased efficiency and reduced labor costs. | 50% reduction in production time. |

| Eco-friendly Materials | Utilizing recyclable materials for sustainable production. | Enhanced environmental responsibility. | Achieve 30% reduction in carbon footprint. |

| Smart Quality Control | Implementation of AI for real-time quality monitoring. | Higher product reliability and reduction in waste. | 90% reduction in defect rates. |

| Custom Design Technologies | 3D printing technology for personalized wall panel designs. | Enhanced customer satisfaction through customization. | Double sales in custom product lines. |

| Blockchain for Supply Chain | Using blockchain for transparency and traceability in supply chains. | Increased trust and accountability. | 80% improvement in supply chain traceability. |

Best Way To Choose Pvc Wall Paneling Sheet Factory Manufacturers You Can Rely On Your End-to-End Solution

E

Ethan Jones

Very pleased with the quality! The after-sales service team was quick to respond and provided insightful information.

11 June 2025

A

Ava Martinez

High-quality product! I was especially impressed with how the support staff approached my concerns with such expertise.

09 June 2025

A

Ava Rodriguez

The product works perfectly, and the customer service is outstanding. They really know their stuff!

26 July 2025

E

Elijah Brown

Product quality is exceptional. The after-sales staff were professional and resolved my issues immediately.

03 June 2025

A

Alexander Collins

The product quality is superb! The after-sales team were polite and expertly trained.

03 July 2025

J

Jessica Holloway

The professionalism of the customer service team was outstanding. They resolved my inquiries promptly and thoroughly, giving me confidence in my purchase.

20 June 2025

Hot Selling

Hot Selling