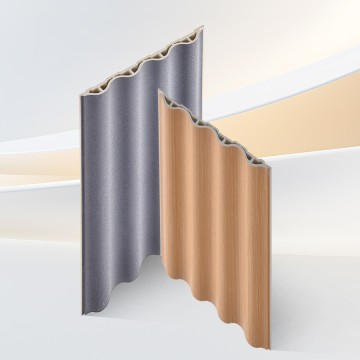

WPC Exterior Waterproof Products | Reliable Manufacturers and Trusted Factory Supplier

Enhance your outdoor projects with premium WPC (Wood Plastic Composite) offerings from Shandong Xiangying New Materials Technology Co., Ltd. Our advanced materials deliver outstanding waterproofing while ensuring durability and longevity for a range of applications such as decking, fencing, and outdoor furniture. These WPC products are engineered to withstand moisture, UV exposure, and wear, making them perfect for any environment. Crafted from high-quality recycled materials, our solutions are eco-friendly and provide a stylish alternative to traditional wood. With a unique combination of natural wood fibers and plastic, they retain the beauty of wood without the issues of rot, splintering, and fading. Choose from a wide selection of colors and finishes that complement any design aesthetic. Rely on Shandong Xiangying New Materials Technology Co., Ltd. for innovative, durable, and sustainable WPC products that endure the elements and enhance your space.Tips & Tricks for Wpc Exterior Water Proof Manufacturers Custom Solutions, in 2025

In 2025, the demand for durable and water-resistant materials is more pronounced than ever, especially in the realm of WPC (Wood Plastic Composite) exterior solutions. Manufacturers must not only deliver high-quality products but also innovate their offerings to meet the evolving needs of global buyers. Here are some essential tips and tricks for WPC exterior waterproof manufacturers looking to tailor custom solutions for their clients. Firstly, understanding the specific requirements of your clients is crucial. Conduct detailed consultations to grasp their unique applications, be it decking, fencing, or cladding. By providing personalized assessments and recommendations, you can showcase your commitment to service and sincerity—a principle that has defined our company for over a decade. This approach not only builds trust but also positions your products as valuable investments in a client's project. Secondly, leverage cutting-edge technology in your manufacturing processes. Innovations such as advanced co-extrusion techniques can enhance water resistance and longevity. Additionally, consider eco-friendly materials and sustainable practices, as global buyers increasingly prioritize sustainability in their procurement decisions. By aligning your offerings with these trends, you can foster mutual benefit and win-win cooperation, ensuring that both your brand and your clients thrive in the competitive market.

Tips & Tricks for Wpc Exterior Water Proof Manufacturers Custom Solutions, in 2025

| Tip/Trick | Description | Expected Outcome | Implementation Time |

|---|---|---|---|

| Choosing Quality Raw Materials | Select high-performance materials that enhance water resistance. | Increased durability and lifespan. | 1-2 weeks for sourcing. |

| Advanced Coating Techniques | Utilize cutting-edge coating methods for enhanced protection. | Improved water repellency. | 2-3 weeks for application. |

| Regular Quality Testing | Implement ongoing quality control measures for products. | Consistent product performance and reliability. | Continuous process. |

| Customer Feedback Loop | Establish a system for gathering customer insights. | Enhanced product development based on real user feedback. | Ongoing process. |

| Eco-Friendly Solutions | Focus on sustainable materials and methods. | Attraction of environmentally conscious consumers. | Variable, depending on sourcing. |

Smart Ways To Wpc Exterior Water Proof Manufacturers Your End-to-End Solution Service Backed by Expertise

E

Ethan Jones

Very pleased with the quality! The after-sales service team was quick to respond and provided insightful information.

11 June 2025

S

Sophia White

Excellent craftsmanship and durability! The after-sales service provided was top-notch—very professional.

11 June 2025

L

Lucas Garcia

High-quality materials used, and the support was incredibly helpful! They really go the extra mile.

02 July 2025

E

Evelyn Clark

Amazing quality! The support staff were not only professional but also very understanding.

12 July 2025

M

Madison Scott

Fantastic experience! The quality of the item is high, and the support service was exemplary.

16 June 2025

R

Robert Sinclair

The durability of this product is impressive. I was pleasantly surprised by the level of support I received post-purchase.

14 July 2025

Hot Selling

Hot Selling